We provide innovative solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market

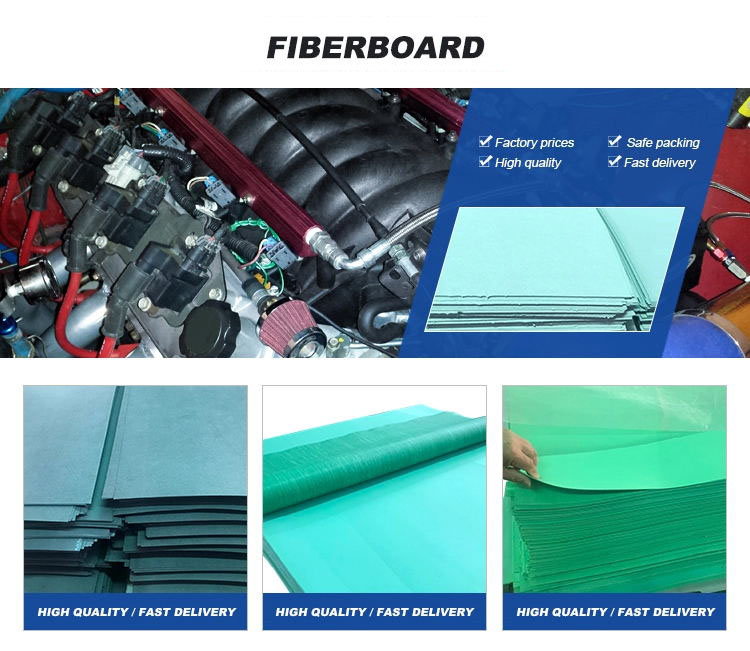

The green fiber sealing material XT-2002 is made of 100% non-asbestos mineral fiber, cellulose and other organic fiber, nitrile rubber, mixed inorganic filler and a variety of functional additives.

Features

* Good oil resistance and compressive strength

* Good product uniformity

* The thickness deviation is small

* The maximum intermittent service temperature can reach 180℃

Product Use

It is mainly used to seal oil, fuel oil, water, coolant and air, etc. And especially suitable for the suction valve pad and cylinder head pad of the fully enclosed refrigeration compresssor.

Rules:

Roll type supply, standard roll width

Special specifications can be agreed with the customer

Physical performance

Property | Unit | Value | Method |

Density | g/cm3 | ≥1.40 | GB/T 22308-2008 |

Tensile Strength,AMD | MPa | ≥14.0 | GB/T 20671.7-2006 |

Compressibility | % | 10.0-25.0 | GB/T 20671.2-2006 |

Recovery | % | ≥45.0 | GB/T 20671.2-2006 |

Fluid Resistance, IRM 903 Oil ( 150℃,5h) | |||

Change in Tensile Strength | % | ≤35.0 | GB/T 20671.3-2006 |

Change in Weight | % | ≤30.0 | GB/T 20671.3-2006 |

Change in Thickness | % | ≤10.0 | GB/T 20671.3-2006 |

Compressibility | % | ≤25.0 | GB/T 20671.3-2006 |

Fluid Resistance, RH-22L Oil ( 150℃,5h) | |||

Change in Tensile Strength | % | ≤40.0 | GB/T 20671.3-2006 |

Change in Weight | % | ≤30.0 | GB/T 20671.3-2006 |

Change in Thickness | % | ≤15.0 | GB/T 20671.3-2006 |

Compressibility | % | ≤30.0 | GB/T 20671.3-2006 |

Binder Type | Full Vulcanization Nitrile Butadiene Rubber | ||