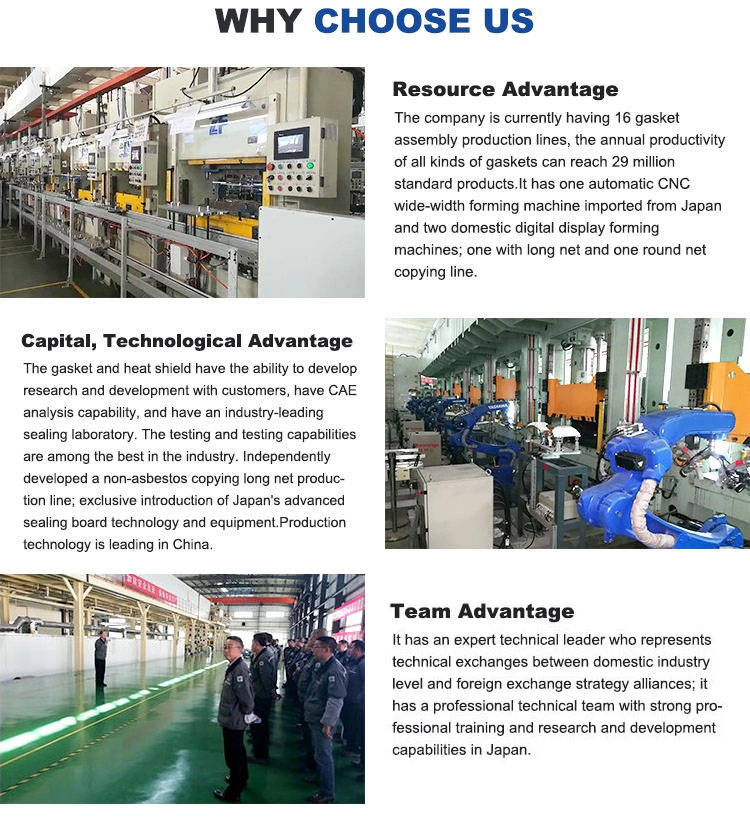

We provide innovative solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market

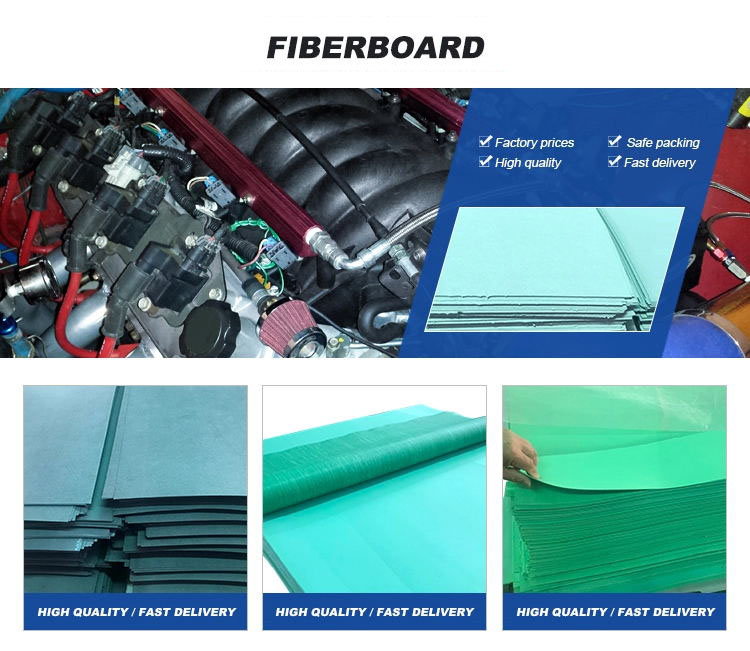

Green fiber sealing material XT-1002 is composed of 100% non-asbestos mineral fibers, cellulose and other organic fibers, nitrile rubber adhesive, mixed inorganic fillers and a variety of functional additives, and is prepared through the Fourdrinier continuous papermaking process.

Features

* High compression rate

* Good interface sealing

* Excellent compressive strength

* The maximum intermittent use temperature is 180℃

Product Use

It is recommended to seal oil, fuel, water, air and other media, especially suitable for sealing small gasoline engines and vehicle pumps.

Rules

Coils: standard roll width 1280mm

Products can be customized according to your requirements.

Physical performance

Property | Unit | Value | Inspection Method |

Density | g/cm3 | ≥1.20 | GB/T 22308-2008 |

Tensile Strenth, AMD | MPa | ≥10.0 | GB/T 20671.7-2006 |

Compressibility | % | 15.0-30.0 | GB/T 20671.2-2006 |

Recovery | % | ≥40.0 | GB/T 20671.2-2006 |

Creep Relaxation | % | ≤35.0 | GB/T 20671.5-2006 |

Fluid Resistance, IRM 903 Oil (150℃, 5h) | |||

Change in Weight | % | ≤35.0 | GB/T 20671.3-2006 |

Change in Thickness | % | ≤20.0 | |

Fluid Resistance, Distilled Water (RT, 22h) | |||

Change in Thickness | % | ≤20.0 | GB/T 20671.3-2006 |

Nitrogen Sealability (Internal pressure 0.21MPa) | |||

Flange Pressure 17.2 MPa | Ml/h | ≤150.0 | GB/T 27793-2011 |